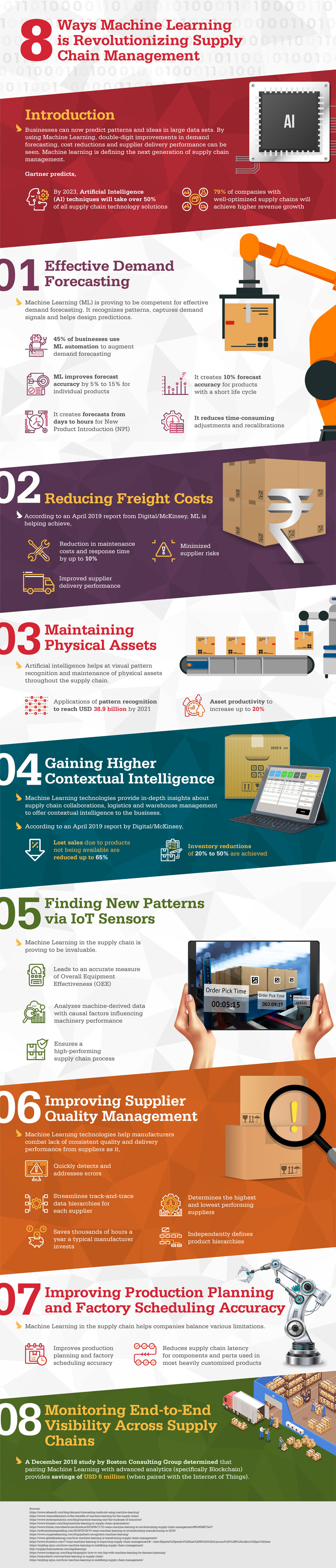

Machine learning has been one of the most promising technologies to discover new patterns in the supply chain. Its multiple capabilities are essential for business success in providing accurate information and predictions and recognizing patterns. It gives reliable solutions even when faced with huge amounts of data. In today’s era, where businesses are striving to reduce costs, increase profits and enhance customer satisfaction, technologies like machine learning offer a window of opportunity. Let’s get a complete insight into how machine learning is revolutionizing supply chain management with the infographic listed below.

Introduction

Businesses can now predict patterns and ideas in large data sets. By using Machine Learning, double-digit improvements in demand forecasting, cost reductions and supplier delivery performance can be seen. Machine learning is defining the next generation of supply chain management.

Gartner predicts:

- By 2023, artificial intelligence (AI) techniques will take over 50% of all supply chain technology solutions

- 79% of companies with well-optimized supply chains will achieve higher revenue growth

There are many ways machine learning is revolutionizing supply chain management.

Machine Learning Algorithms

Machine Learning (ML) is proving to be competent for effective demand forecasting. It recognizes patterns, captures demand signals and helps design predictions.

- 45% of businesses use ML automation to augment demand forecasting

- Creates 10% forecast accuracy for products with a short life cycle

- Improve forecast accuracy by 5% to 15% for individual products

- Up to 40% forecast accuracy for weather-sensitive product groups

- Internal and external sources of information to make data-driven predictions

- Creates forecasts from days to hours for new product introduction (NPI)

- Reduce time-consuming adjustments and recalibrations

Reducing freight costs

According to an April 2019 report from Digital/McKinsey, ML is helping achieve:

- Reduction in maintenance costs and response time by up to 10%

- Improved supplier delivery performance

- Minimized supplier risks

Maintaining Physical Assets

Artificial intelligence helps at visual pattern recognition and maintenance of physical assets throughout the supply chain.

- Applications of pattern recognition to reach USD 38.9 billion by 2021

- Asset productivity to increase up to 20%

Gaining Higher Contextual Intelligence

Machine Learning technologies provide in-depth insights about supply chain collaborations and logistics and warehouse management to offer contextual intelligence to the business. According to an April 2019 report by Digital/McKinsey:

- Lost sales due to products not being available are reduced up to 65%

- Inventory reductions of 20% to 50% are achieved

Forecasting Demand

Machine Learning in the supply chain considers causal factors that influence demand for a new product. The algorithms use,

- The pragmatic approach of asking channel partners

- Direct and indirect sales teams

- Advanced statistical models

- Reduction in forecasting errors by 20% to 50% as per McKinsey study

Finding New Patterns via IoT Sensors

Machine Learning in the supply chain is proving to be invaluable:

- Leads to an accurate measure of Overall Equipment Effectiveness (OEE)

- Analyzes machine-derived data with causal factors influencing machinery performance

- Ensure a high-performing supply chain process

Improving Supplier Quality Management

Machine Learning technologies help manufacturers combat lack of consistent quality and delivery performance from suppliers as it,

- Quickly detects and addresses errors

- Determines the highest and lowest performing suppliers

- Streamlines track-and-trace data hierarchies for each supplier

- Independently defines product hierarchies

- Saves thousands of hours a year a typical manufacturer invests

Improving Production Planning and Factory Scheduling Accuracy

Machine Learning in the supply chain helps companies balance various limitations.

- Improves production planning and factory scheduling accuracy

- Reduces supply chain latency for components and parts used in most heavily customized products

Monitoring End-to-end Visibility Across Supply Chains

A December 2018 study by Boston Consulting Group determined that pairing Machine Learning with advanced analytics (specifically Blockchain) provides savings of USD 6 million (when paired with the Internet of Things)

Source:-https://www.altexsoft.com/blog/demand-forecasting-methods-using-machine-learning/

Source:-https://www.chainofdemand.co/the-benefits-of-machine-learning-for-the-supply-chain/

Source:-https://www.enterrasolutions.com/blog/machine-learning-and-the-business-of-tomorrow/

Source:-https://www.bluepiit.com/blog/machine-learning-in-supply-chain-optimization/

Source:-https://www.mygreatlearning.com/blog/pattern-recognition-machine-learning/

Source:-https://www.globaltrademag.com/how-machine-learning-is-transforming-supply-chain-management/

Source:-https://erpblog.iqms.com/how-machine-learning-is-redefining-supply-chain-management/

Source:-http://supplychaininstitute.com/tag/learning/

Source:-https://marutitech.com/machine-learning-in-supply-chain/

Source:-https://erpblog.iqms.com/how-machine-learning-is-redefining-supply-chain-management/